Sustainability Management in Environment and Energy Dimensions

Environmental Policy and Practice

The Company is well aware of the importance of the environment; therefore, the policy and goals are clearly defined and reviewed for continuous improvement annually. Employees at all levels have to adhere.

According to the 2022 Environmental Management Policy, Contribute to realizing an affluent society that achieves both sustainability and safe, secure, and comfortable lifestyles through all company activities, which the Company communicates and publicizes the said policy to internal and external that covers the stakeholders of the organization as well. The essential issues in environmental conservation activities are entitled to the system as follows:

1. Aim for continuous improvement and new value creation by implementing an environmental management system

2. Contribute to climate change countermeasures and the formation of a recycling-based society by promoting environmentally friendly designs (3Rs, resource-saving product development) aimed at global environmental advancement.

3. Promote reduction of greenhouse gas and strengthening of management for a carbon-free society.

4. Promote energy conservation by pursuing an efficient production method.

5. Promote waste generation control, resources recycling, efficient use of water and reduction of pollution load.

6. Disseminate the environmental policy, provide technical guidance, and strive for ecological improvement activities for all employees, affiliated companies and cooperating companies as a whole SCM.

7. Strengthen communication with local communities and raise awareness of environmental conservation by participating in local volunteer activities.

8. Comply with environmental laws and regulations and other requirements to improve the management level.

Environmental Performances

The Company focuses on natural resource conservation activities by using resources efficiently and adopting the principle of 3Rs (Reduce, Reuse, Recycle) as a guideline for production activities to make the use of resources worthwhile such as;

• Encourage each department to carry out Paperless projects to reduce paper usage. Encourage each department to carry out Paperless project to reduce paper usage including the application of appropriate IT technology such as Simmpro program (Simmpro maintenance management system), E-Quotation request, Alfresco software, Memo online, Training application, etc.

• Reduce product electrical power.

• Reduce the weight of finished goods.

• Reduce plastic pellets, oil paints and powder paints and reduce the metal scrap.

• Promote the reuse of plastic scrap, POM runner and plastic runner.

• Promote the reuse of treated water by installing a water filtration system.

• Reduce the use of plastic bags foam container inside the Company.

• Promote and support green procurement by considering ordering office equipment and consumables that have been certified for environmentally friendly products such as green label products green basket labels Carbon Footprint Reduction labels, etc.

• Organize training for all new employees on environmental conservation.

Activities focusing on controlling the operations of various activities to prevent environmental toxicity such as;

• Carrying out a campaign for recycling waste sorting to reduce the amount of waste that must be taken to the landfill and establish a clean and orderly waste sorting center.

• Select industrial waste disposal operators that are authorized by the Department of Industry only.

• Change the metal material to a pre-coated metal (PCM) to cancel the painting process.

• Improve the quality of wastewater before discharging into public canals by controlling water quality before releasing it to be 20% more stringent than the law. Install a real-time water quality monitoring and alerting system. When the water quality is lower than the control criteria, the floodgate will close automatically to prevent it to the outside.

• Conduct environmental quality measurements, including wastewater quality, effluent quality, rainwater gutter, the air exhausted from the chimney, and noise level, to follow up and report to concerned government agencies.

• Checking the condition of the shuttle bus to reduce the emission of black smoke.

• The Company has been certified Green Industry Level 4 (Green Culture) by the Ministry of Industry, which represents an environmentally friendly business operation adhering to business operations with social responsibility inside and outside the Company, aiming for sustainable industrial development throughout the supply chain.

Energy Policy and Practice

The Company dedicated itself to producing energy-saving products for consumers and manage the energy used in the production system. Therefore, the Company has applied an energy management system since 2010, which is the duty of all executives and employees. In addition, in 2020, the Company certified with energy management standard ISO 50001: 2018 from TUV NORD (Thailand) Ltd. The Company has set an energy conservation policy to be operating guidelines. The Company is the first in the Mitsubishi Electric group that promote energy efficiency and maximum benefits. The Company has focused on energy conservation activities and energy management of machinery and equipment with significant-high energy consumption by changing or finding energy-saving devices to replace them with the following measures.

Electrical Measures

1. Changing 28-watt light bulbs to be 18-watt LED bulbs total 80 sets, saving electricity 2,304 kWh/year.

2. Setting the on-off the Cooling Tower system 1 unit at break time, saving electricity 1,944 kWh/year.

3. Replacing the 50 HP No.4-02 air compressor with one unit of high-efficiency air compressor, saving energy 187,404 kWh/year.

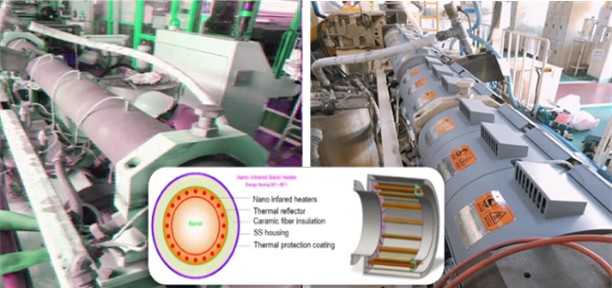

4. Changing the Heater device of the injection molding machine from Band heater to Infrared heater 6 units, saving electricity 71,366 kWh/year.

5. Fixing air leakages of the air compressor system in the production line at building 1, 2, 3, 4, 9, and 11, saving electricity 305,345 kWh/year.

6. Changing the Heater device of the Extrusion from Band heater to Infrared heater 2 units, saving electricity 74,073 kWh/year.

All measures can save electricity 642,436 kWh/year

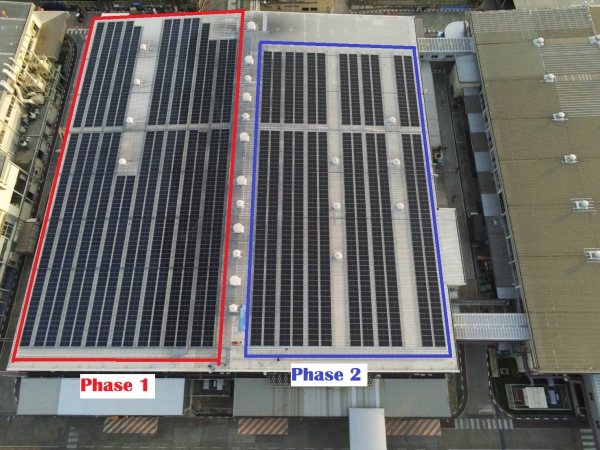

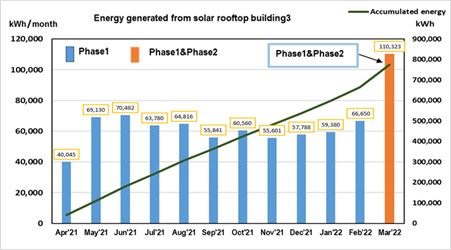

In addition, the Company applied renewable energy use by installing a solar-cell power generation system on the roof of Building 3 with a total size of 939.9 kW, saving electricity 1,403,230 kWh/year and reducing energy costs by 5,781,308 baht.